IBC (Intermediate Bulk Container) liquid filling equipment are a crucial Alternative for industries that handle and package huge volumes of liquid merchandise. Widespread in sectors for instance chemical substances, foods and beverage, prescribed drugs, and industrial production, this equipment are particularly built to fill IBCs quickly, correctly, and safely and securely—assisting enterprises streamline operations, cut down waste, and maintain top quality criteria.

An IBC can be a massive, reusable container commonly Keeping 1,000 litres of liquid. Filling this kind of big volume calls for precision and Command to stop overflows, spillage, and product or service reduction. IBC liquid filling products addresses these issues by automating the job, enabling operators to fill containers proficiently while guaranteeing actual quantity or body weight requirements are satisfied.

There are several different types of IBC filling devices obtainable, such as top rated-fill and bottom-fill units, with regards to the mother nature in the product. As an example, base-fill programs will generally be beneficial for foaming or hazardous liquids to reduce splashing and publicity. The filling procedure is usually managed by flowmeters or electronic weigh scales, ensuring large accuracy and consistency. After the set fill degree is realized, the equipment instantly stops the circulation, lessening operator intervention and likelihood of error.

Contemporary IBC fillers are created with person-helpful controls Bag in Box filling machines and hygienic resources like stainless-metal, creating them to be ideal for each cleanroom environments and harsh industrial conditions. They generally contain features like drip containment, security interlocks, and Cleanse-In-Location (CIP) capacity to meet stringent sector benchmarks and guarantee simple servicing.

Australian maker Flex Pack Provider & Provides gives robust and reliable IBC liquid filling solutions personalized to customer requires. Their machines supports a variety of liquid varieties and container dimensions, from smaller pails to total-size IBCs. Suitable for equally handbook and semi-automatic operations, Flex Pack’s equipment are perfect for businesses trying to find flexible and effective packaging methods.

Making use of IBC liquid filling devices provides a number of essential Gains: it raises productiveness, improves security by minimizing manual managing, makes sure exact filling for top quality Manage, and permits quick batch modifications. This makes it a great expenditure for companies trying to optimise bulk liquid packaging procedures.

In summary, IBC liquid filling equipment are indispensable for industries managing high-quantity liquid packaging. With the proper device in situation, providers can increase performance, keep costs down, and provide steady, significant-high quality final results with every batch.

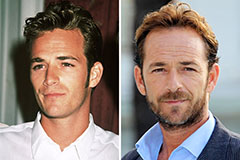

Luke Perry Then & Now!

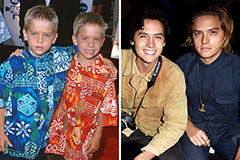

Luke Perry Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!